Americans depend on the oil industry for many of their everyday necessities. From components used in lipsticks and cosmetics to life-saving medical devices like MRI machines, to our phones, and the gas we use to fuel our cars and heat our homes. All of this begins from extracting these resources from the planet and doing so safely and efficiently.

The word petroleum comes from the Latin “petra,” which means “rock” and “oleum,” which means oil. The use of natural resources is nothing new; people have been using nature’s elements for a long time. Today’s demands, however, are bigger as our dependence and use of these natural resources has increased and populations have grown.

It Began With the Demand for More Light

Kerosene lamps were once deemed one of the most important light sources for the everyday American. As demand rose, the need for ‘coal oil’ increased. America’s first petroleum exploration company was the Pennsylvania Rock Oil Company of New York incorporated in 1854.

As companies began experimenting with new technologies, new ideas that implemented a kind of chiseling a hole deeper in the earth, except it used steam power and stronger tools. The country’s first commercial oil well emerged in 1859 when a well just 69.5 feet deep was dug and would consequently transform the American economy forever. You may have heard the story before.

In a woodland valley along a creek in the great state of Pennsylvania, the behemoth of the oil industry was born. This rock oil fuel was much cheaper than whale oil and safer than camphene.

Almost overnight, more states joined Pennsylvania in the search for this new fuel. The need for better infrastructure and techniques meant that engineering would quickly focus on the industry.

The need for machinery, as well as the production, storage, and transportation of this “black gold,” created a massive boom in the economy. Not long after, other states seeking to become ‘production states’ were finding their own black gold. In 1901, Texas joined the endeavor with the “Lucas Gusher.” Then other states joined like Alabama, Alaska, and more. The concurrent innovation in the auto industry would also help the oil industry skyrocket from 150 barrels produced worldwide in 1900 to more than one billion barrels in 1925.

Notable Innovations in the Industry

The drill pipe, invented by Edwin Drake, who was involved with the Pennsylvania Oil Company made great strides to improve the process. Drake is often known as the father of the petroleum industry because it was his technology that revolutionized how crude oil was produced and launched onto the market.

Then came the rotary drill, which was first used in the late 1800s. The rotary drill consisted of a rotating drill bit that could break through rock and hard surfaces, allowing the digging to go deeper. As companies continued digging and exploring new territory, it was clear that oil-digging near shores was far more lucrative. Soon, the need to dig beneath the ocean floor became a big priority.

Special ROVs or (remotely operated vehicles) were developed to get into these hard-to-reach places. The advent of hydraulic fracturing was also a big step towards improving the oil-drilling business.

According to the U.S Department of Transportation’s Federal Highway Administration, the average person drives around 13,500 a year. If you multiply that by how many people are commuting and moving across the United States on any given day, the number is astounding. Oil for our vehicles is not the only use for oil. Its presence in our daily life is really something that is not often acknowledged every day.

The Maintenance Needed for Oil Industry Equipment

There is a lot that goes into operating and maintaining a successful oil rig and oil production site. Here at Remsa USA, we have worked with companies involved in the oil industry by helping them properly maintain their equipment.

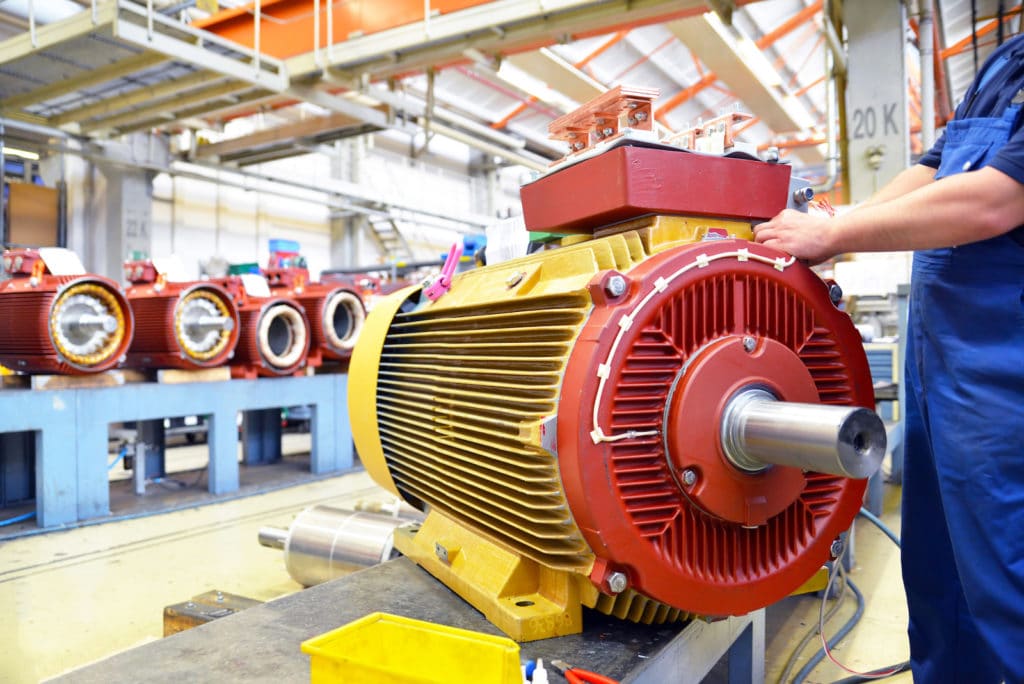

Our experience in electrical field services means that only experienced professionals are going out to deal with what is expensive and necessary machinery to any company. The motors and generators used in the oil industry can and are often exposed to incredibly harsh conditions. Issues with the motor can quickly wreak havoc in any operation, as those that have operated it will know all too well.

The importance of serving generators and motors goes without saying. The downtime needed for regular maintenance is an important expense and you want to trust only professionals to get the job done. After all, how you accomplish this maintenance and its effectiveness can affect your bottom line. It’s why we’re here. At Remsa USA, we want to ensure that your operation doesn’t skip a beat.