Providing Professional Assistance with Rewinding Electric Motors

The professionals at Remsa USA have been able to help several customers with a number of problems when it comes to rewinding their electric motors. Oftentimes, customers allow their motors to run until they burn up. Whether your motor has just begun to fail to run or has been faulty for a while, we can tend to your systems, nonetheless.

Our Rewinding Services for Electric Motors

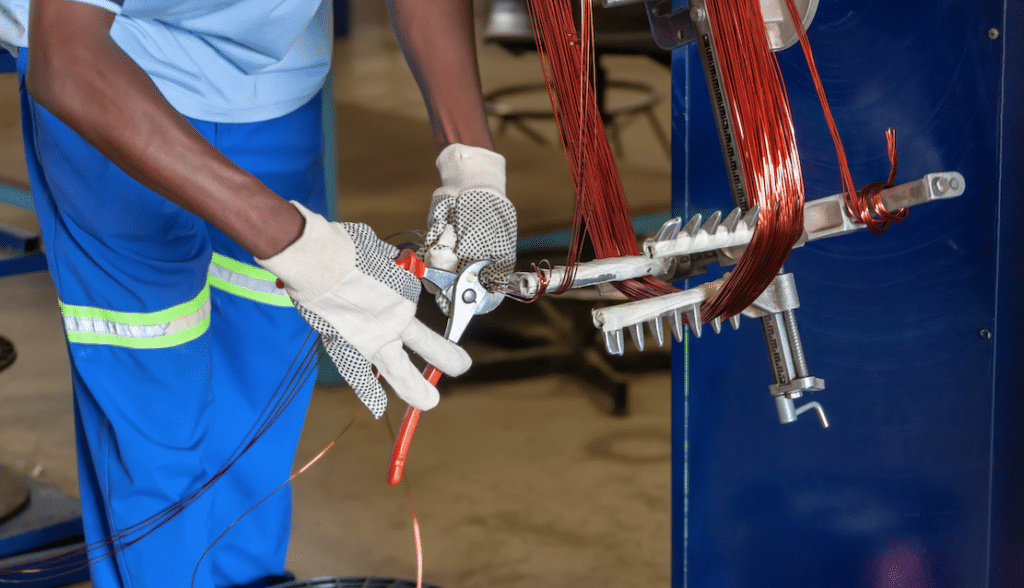

Rewinding electric motors calls for an intricate process of precision and diligently working around parts. We go through the following steps:

• Steam clean the stator

• Installation of new coils to stator slots

• Lacing additions

• Curing the motor and re-testing

These steps are necessary in order to give back customers their motors in a completely refurbished condition. You can confide in the professionals at Remsa USA as you will find yourself with a quality motor that works as good as new.

The Remsa USA Team is Ready to Help

Our employees are equipped with the skills and tools needed to successfully rewind your electric motor. Our departments work closely together to provide customers with quick turnaround times with high-quality maintenance. We are honored to grant exceptional customer service with faulty motors.

Common Signs Your Electric Motor is Due for a Rewind

Broken or corroded parts

Deteriorated materials usually contain an excess of oil, grease, or rust. Corrosion is a common problem with motors as it can impede efficiency.

Readings of inconsistent short circuit coils

Winding resistance is integral to a motor’s functions. If coils are beginning to run short, resistance will become less and less prevalent.

Low insulation resistance

This is usually caused by damage, excessive vibrations, or old age of the motor. Readings for insulation resistance should be recorded over 2M in ohms. It is below this value, it is likely that your motor is in need of rewinding.

Power surges

This often occurs after lighting has struck the motor. An excess of voltage can burn the motor out and fail to release large amounts of energy.

Bearing failures

These failures are usually due to mechanical and thermal causes. Currents that flow through induction motor bearings can also induce premature bearing failure.

Providing Great Results and Peace of Mind

The team at Remsa USA has unwound an endless amount of motors. We are more than familiar with their inner makeup, no matter the model or brand of your motor. When you choose us, you can expect that your motor will run flawlessly for years to come.