Pump Laser Alignment at Remsa USA

What to Expect from Our Pump Laser Alignment Services

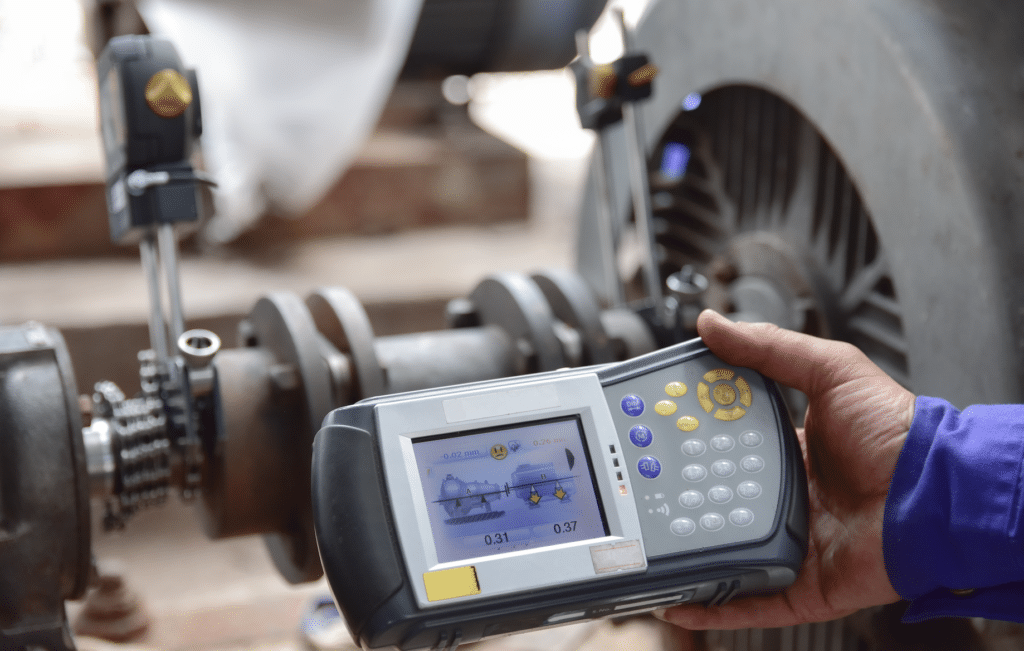

Our laser alignment services are not solely equipped to improve manufacturing efficiency. Incorporating laser shaft alignment for your motor-pump can also help to minimize the risk to beam injuries during these procedures. In a long-term perspective, shaft alignment can increase your profitability through your ability to provide consumers with faster results and industrially-based services. When you choose Remsa USA, you can expect us to make specific measurements and apply laser alignment accordingly to your equipment’s positions and target of work.

Industries and Companies We Work With

Remsa USA has been able to proudly offer and provide pump and shaft laser alignment for the following industries:

• Mining

• Wind and renewable energy

• Water and utility

• Electricity and municipality

• Power stations

• Agricultural services

Trust the Remsa USA Inc Team for High-Quality Services

Remsa USA has been El Paso’s main source for pump manufacturing, refurbishing, and repairs for decades on end. We encourage our customers to incorporate laser and shaft alignment for their motor-pumps to reduce the number of production errors that could potentially run into. With this, there is less need for maintenance and repairs. Remsa USA is always available when you find yourself in need of power delivery services, but we also aim to help you maximize efficiency by doing the job right the first time around.

Issues That Require Pump Laser Alignment

Premature bearings

This can be caused by a number of factors: excessive lubrication, overload, improper handling, and installation. These pieces of equipment need immediate attention as they cab reduce operation efficiency and increase downtime.

Shortened mechanical seal

Shorten seal life can potentially summon over-heating and excessive vibration problems. Proper sealing can allow you to start your pump with a concealed discharge valve.

Shaft failures

Shaft failures can drastically reduce the life of a pump. Our professionals can assess the fluctuating load and fatigue, the most common sources of failure.

Misalignment

Misalignment occurs when the equipment deviates or shifts from a pump’s natural position. Excessive overload is the most common cause of misalignment.

Vibration, noise, inefficiency

Vibrations can be damage-inducing. These inefficiencies usually occur when pump suction is excessive and during misalignment.