Transformer Repair and Testing

The Best In The Industry

Our Transformer Repair Services

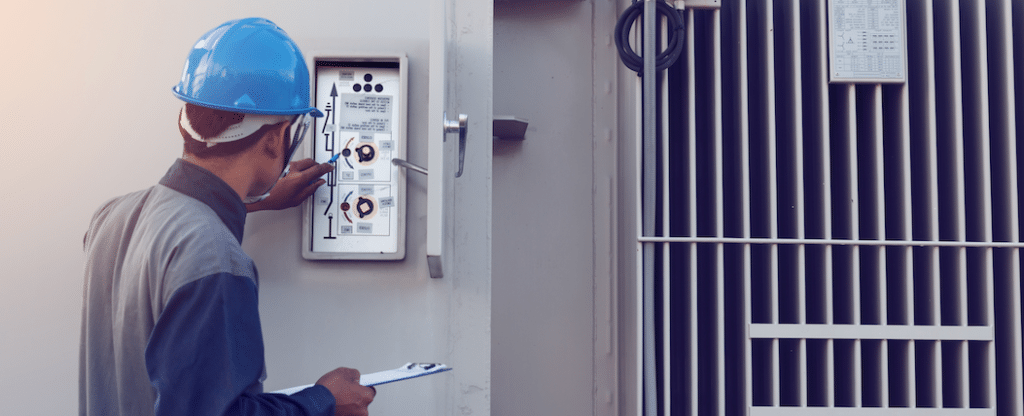

Transformer and switchgear repair

This field of repair includes cable testing, power factor testing, and full electrical testing. Conducting these tests helps to prevent system failures that can disrupt facility productions.

Coil rewind

Coil rewind is optimal for retrofits and is important to take care of as your transformer can withstand only so much rewind. If your coil has severely severed, we can assess yours with the proper equipment and procedures.

Field testing

This process includes being able to catch potential areas for failure within your transformer before they grow to worsen. We implement field testing accordingly to the model and make of your transformer.

Complete failure analysis

Collecting data of your transformer allows our professionals to determine the root cause of any internal or performance failures. Preventing the recurrence of failure is also included in complete failure analysis.

Oil analysis

Transformers require fresh and healthy oils in order for your system to run properly and smoothly. Oil analysis also includes monitoring other oil-lubricated systems.

Leak repair

Whether your transformer runs on oil or gas, we can seal active leaks within minutes. By doing so, there’s no need for remanufacturing your transformer entirely.

Why You Should Choose Remsa USA Inc for Repair

The team at Remsa USA is comprised of experienced engineers and technicians that are enabled to carry a wide range of power repair services that are not easily found with other industrial-based companies. With our emergency and non-emergency services, comprehensive transformer repair and power management can be implemented within your facility or plant for smooth production. Power failure can happen at any time any day, therefore, it is our pleasure to make our repair and services available to you when you need them most.

We Work on Oil-Filled, Dry Type, and Special Design Transformers

At Remsa USA, we offer transformer repair and refurbishing for the following:

Oil-filled

These transformers require specifically designed material that meet the physical, electrical, and thermal requirements when it comes to applying transformer oil to extend its life span.

Dry-type

These transformers run on colled air as opposed to cooled liquids. The use of cool air allows the transformer to cool the coils as well for proper functioning.

Special-design

These transformers enable industrial settings to conduct a wide load of power supply without interruptions and for hours on end. These transformers are often used for agricultural use and production.

If you have any questions regarding different models and makes of your transformer, contact us today at

(915) 855-8621.

Industries We Serve

• Oil and gas

• Mining

• Wind and renewable energy

• Power stations

• Water and municipality

• Electric

• Agricultural

Quick, High-Quality Service Guaranteed

Remsa USA prides itself on providing unmatched services and availability in order to best meet your transformer repair and needs. We have been the leading provider of repairs for transformer, motor, and power induction equipment for large companies responsible for providing populated areas with the electricity we need to fuel our everyday obligations. Additionally, clients are quick to choose our professionals due to our quick turnaround times. We provide high-quality repair within a matter of hours, even minutes, to get your transformer back in its natural working condition.